Stellgitter Metall

Metallurgical aspects of welding Stellite 12 to Type 316L ...

This page contains many information about Stellgitter Metall. In addition, the dilution between the filler metal (Stellite 12) and the base metal is almost non-existent, as shown in the EDS map of the fusion line (Fig 2). This suggests that in this particular case, there was an issue in the welding process which led to this low dilution—such as an incorrect temperature causing not enough base metal and .... Stellite ® is a non-magnetic alloy which contains a variety of different metal components with the main elements being cobalt and chromium. The material itself has been around since the 1900s and was originally seen as a substitute for traditional metal cutlery which suffered from general wear and tear and was also prone to staining.. The yield strength of conventional cast and powder metallurgy Stellite 6 was about 541–662 MPa, while laser consolidation increased the yield strength to 751 MPa (vertical direction) and 1023 MPa (horizontal direction), representing an increase of 15%–90%. The LC Stellite 6 material was also 25%–55% harder than conventional Stellite 6.. Kennametal-Stellite offers a wide variety of cobalt and nickel based alloys under the Stellite™, Nistelle™, and Tribaloy™ brand names. These alloys can be used to solve difficult high-heat, erosion, and corrosion problems.. Stellite 1 can be supplied as steel plate/ sheet, round steel bar, steel tube/pipe, steel stripe, steel billet, steel ingot, steel wire rods. electroslag, forged ring/ block,etc. TEL:+86-13880247006 E-mail: [email protected].

long stellite cobalt rod bar

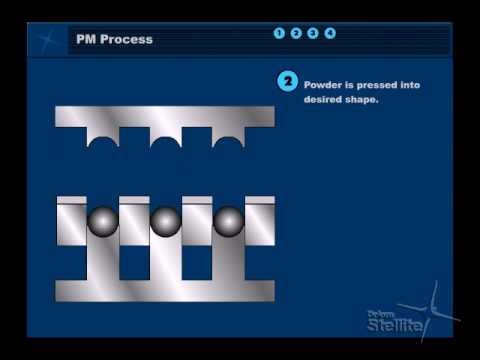

Stellite: Brand: Bhagyashali Metal: We have trusted names in the industry in offering a wide range of Stellite 6 Plates. Manufactured using the best quality inputs under the direction of experts, these plates are highly demanded in the market. Apart from this, these plates can be availed from us in varied sizes.. Stellite alloys are produced by a range of different processes or methods including wrought or hot forging, hardfaced deposit, powder metal and casting depending on teh final appication. Stellite is more difficult to machine and grind than steel, and hence requires high performance processing equipment and specialized machining tools.. Kennametal’s Stellite™ group is the premiere manufacturer of high-alloyed metal powders for hardfacing applications. We deliver a variety of powder sizes with superior chemistry, morphology, flowability and density.. Stellite is a trademarked name of Kennametal Inc. Prior to that it was owned by Union Carbide, Stellite Division. Invented by Elwood Haynes in the early 1900s as a material for making cutlery that wouldn't stain or require constant cleaning.. Kennametal Stellite™ manufactures consumable weld overlay materials as cast rod, cored wire, electrodes, and powder, with a special focus on nickel and cobalt base materials. A wide range of standard alloys (chemistry and dimensional) allows the flexibility to provide custom materials to unique specifications. View Products Below..

Duration: 06:45. Views: 4000+

Duration: 01:37. Views: 5000+

Duration: 05:44. Views: 13000+

Duration: 00:38. Views: 400

Duration: 07:41. Views: 5000+

Duration: 10:06. Views: 14000+

Post a Comment for "Stellgitter Metall"